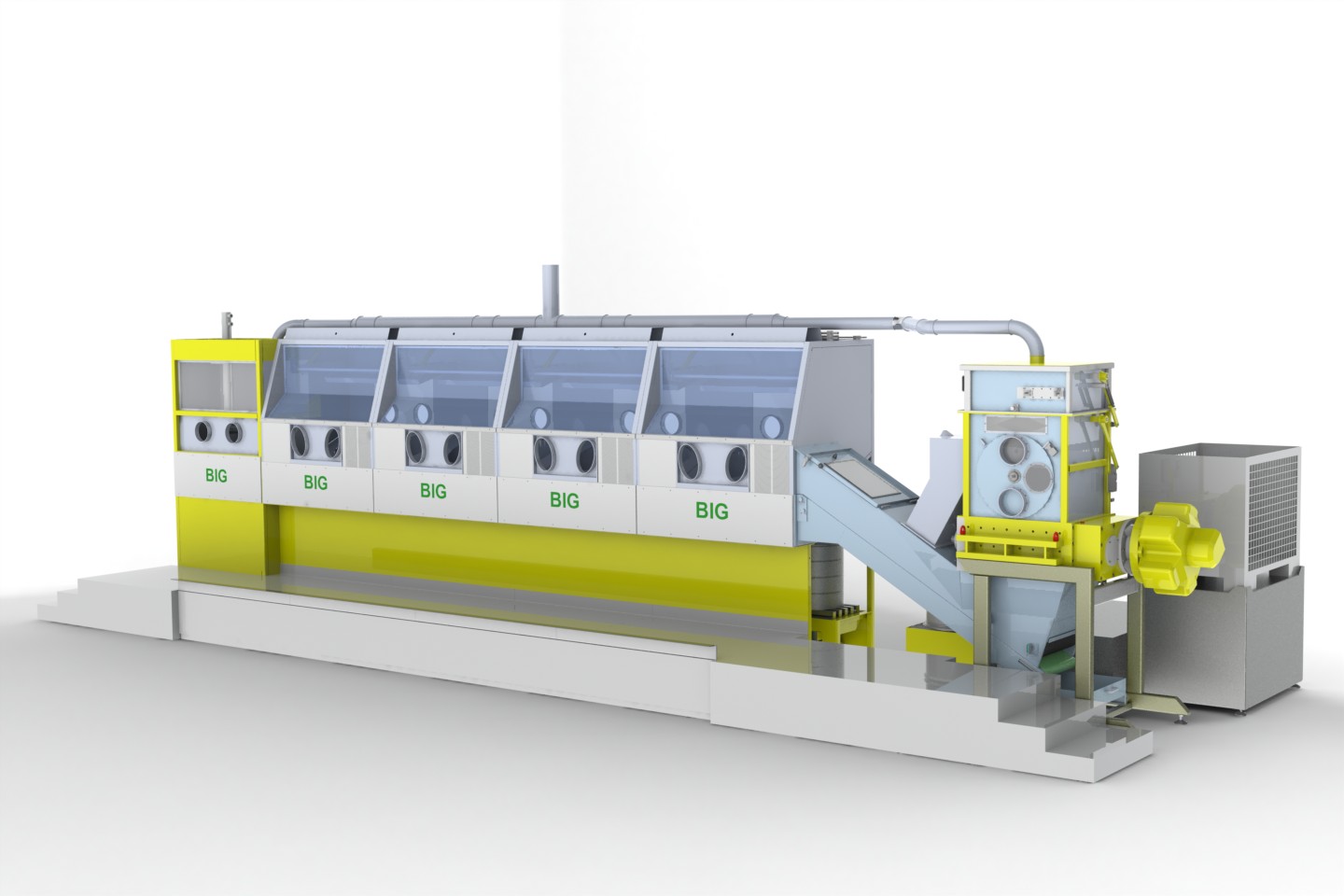

BIG Entsorgungstechnologien GmbH manufactures Sorting Boxes for low-active and intermediate active contaminated wastes in accordance with the specification of the clients.

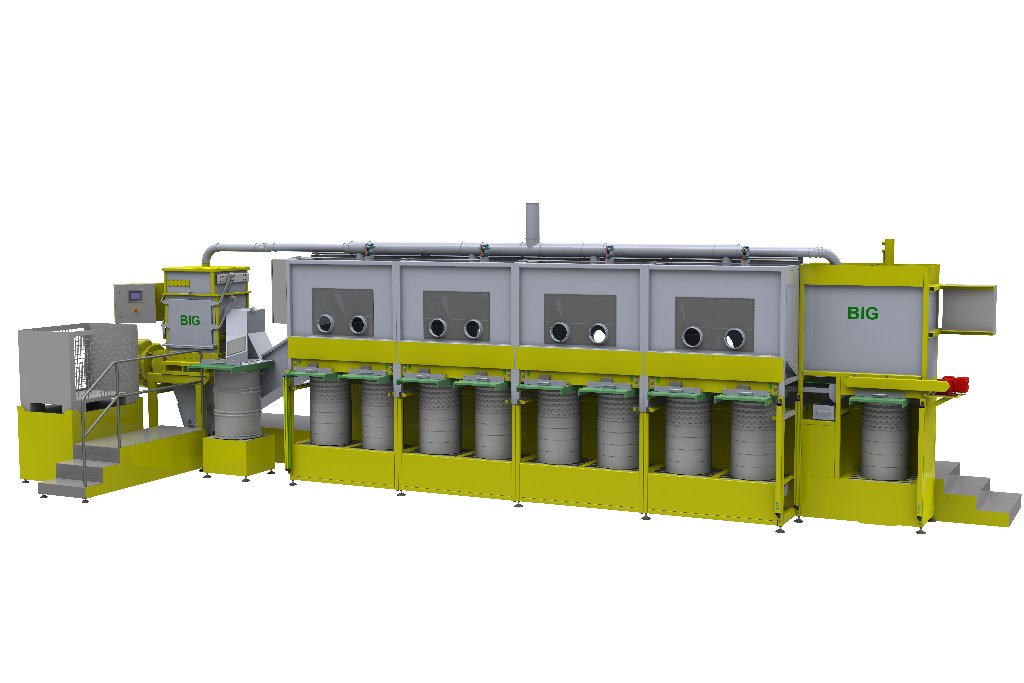

The Sorting Box (Glove Box) is performed as a stainless steel housing made of 4mm thick stainless steel with Belt Conveyor to forward solid waste to the working places and a Tool Tray for storage of sorting tools inside. The Sorting Box includes dropping holes with pneumatically driven covers to be opened for the Drums. The base frame of the Sorting Box is welded from carbon steel profiles and coated with a decontaminable paint.

Windows made of 4mm poly carbonate ensure a good view across the whole sorting area. The Sorting Box illumination assures a good and glare-free view during sorting.

The dropping holes are behind the Sorting Belt. The sorted waste will be thrown into 200l Drums for wet or dry compactable waste and 400l Drums for non-compactable waste are docked to receive the waste which is dropped after sorting through the holes into the relevant drum.

The dropping holes are behind the Sorting Belt. The sorted waste will be thrown into 200l Drums for wet or dry compactable waste and 400l Drums for non-compactable waste are docked to receive the waste which is dropped after sorting through the holes into the relevant drum.

Pneumatically driven docking units are provided to dock and undock drums to the dropping holes.

The Conveyors for Sorting Station are used to place empty drums in the sorting positions and remove filled drums from the sorting positions. The interfaces between the dropping holes and the drums are sealed. The dropping holes are provided with covers in order to close the dropping holes when no drums are docked after a drum is filled and shall be exchanged, or after sorting campaign is finished.

The Conveyors for Sorting Station are used to place empty drums in the sorting positions and remove filled drums from the sorting positions. The interfaces between the dropping holes and the drums are sealed. The dropping holes are provided with covers in order to close the dropping holes when no drums are docked after a drum is filled and shall be exchanged, or after sorting campaign is finished.

One pair of neoprene gloves is provided at each sorting position on the front side of the Sorting Box. The gloves allow proper sorting of the waste and all areas for sorting in the Sorting Box can easily be reached. The glove openings at the sorting stations are movable in the horizontal direction in order to facilitate the sorting process for operating personnel.

One pair of neoprene gloves is provided at each sorting position on the front side of the Sorting Box. The gloves allow proper sorting of the waste and all areas for sorting in the Sorting Box can easily be reached. The glove openings at the sorting stations are movable in the horizontal direction in order to facilitate the sorting process for operating personnel.

One operator platform, adjustable in height, is located in front of the Sorting Box in order to allow good operability when sorting.

The solid waste coming from the 200l Drum via Lifting and Tilting Device is spread on the Sorting Belt. This section of Lifting and Tilting Device includes a collecting pan for drainage of liquids coming from wet solid waste to the Wastewater outlet.

Also, a dose rate instrumentation is integrated into the Sorting Box in order to detect waste with high dose rates.

In order to prevent the environment from contamination which is generated when feeding the Sorting Box and while sorting, the Sorting Box and Lifting and Tilting Device are connected to the Ventilation System.

A fold away Tool Tray, which can be moved at all over the Sorting Box, is available to place hand tools needed for sorting above.

A local Operator Panel is provided at the Sorting Box to control the functions of this device.

Alternatively, a pre- or post-shredding can be added to the Sorting Station.

Technical Data:

Number of Sorting Places: 3+1 or 4+1

Compaction Force: 80-200 kN (adjustable)

Throughput: 4 m³/Tag

Exhaustion: 200 m³/Stunde

Number of Drums:: 3 + 1 to 8 + 1 + 1

Size of Drums: 200l / 400l

Feeding Station: 200 l Drum/ 300 kg

Power Supply: 400/380V; 50 Hz

Rated Power: 6 – 30kW